Features

Technology and Services

- Investment Casting

- Alloy Development

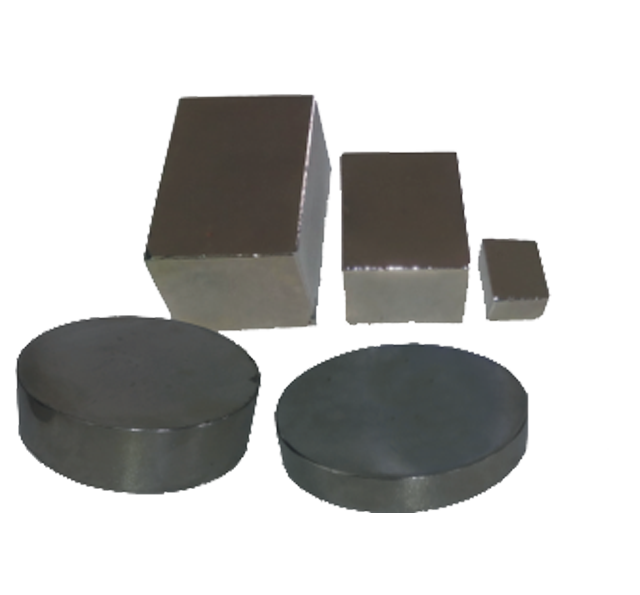

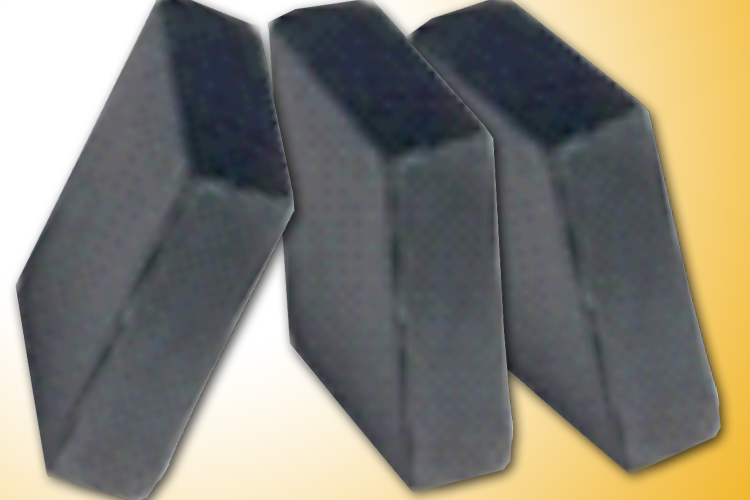

- Powder Metallurgy

- Coating

Technology and Services

- Magnet Development

- Materials Characterization

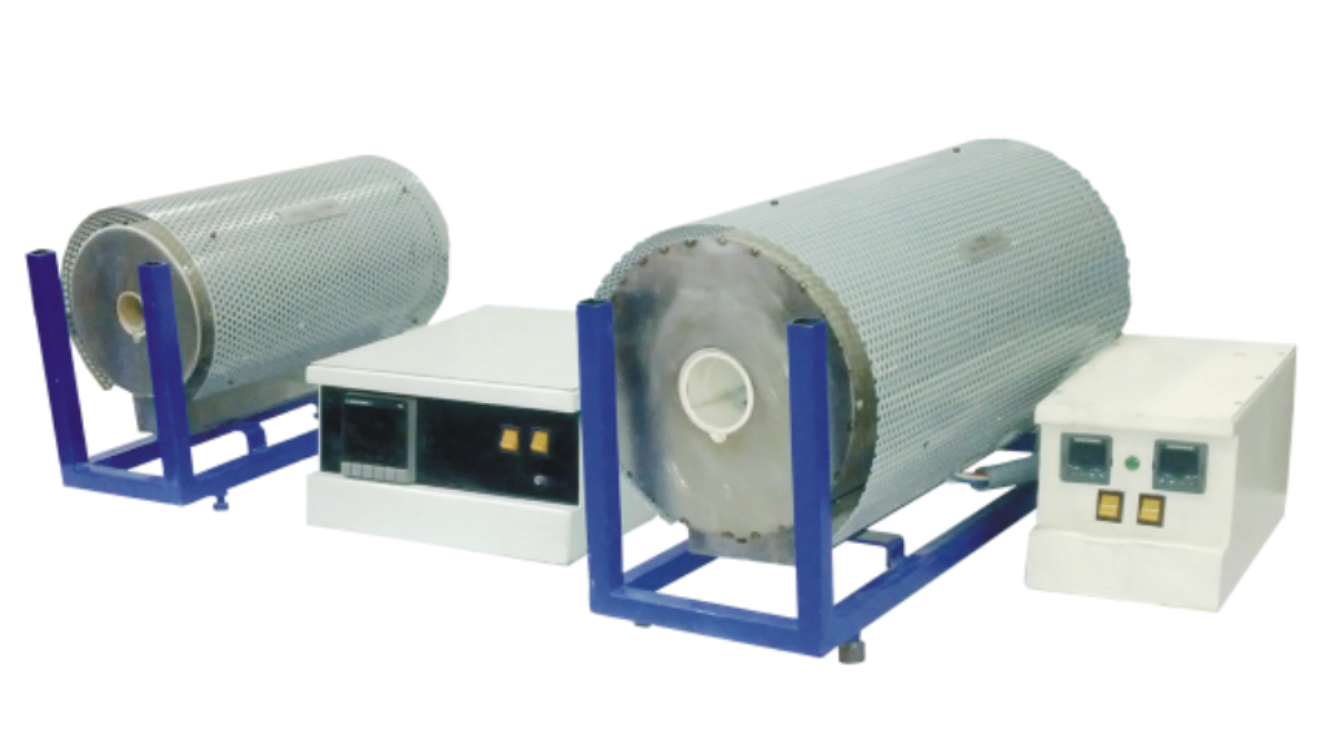

- Equipment Manufacturing

- Electromagnet Manufacturing and Calibration